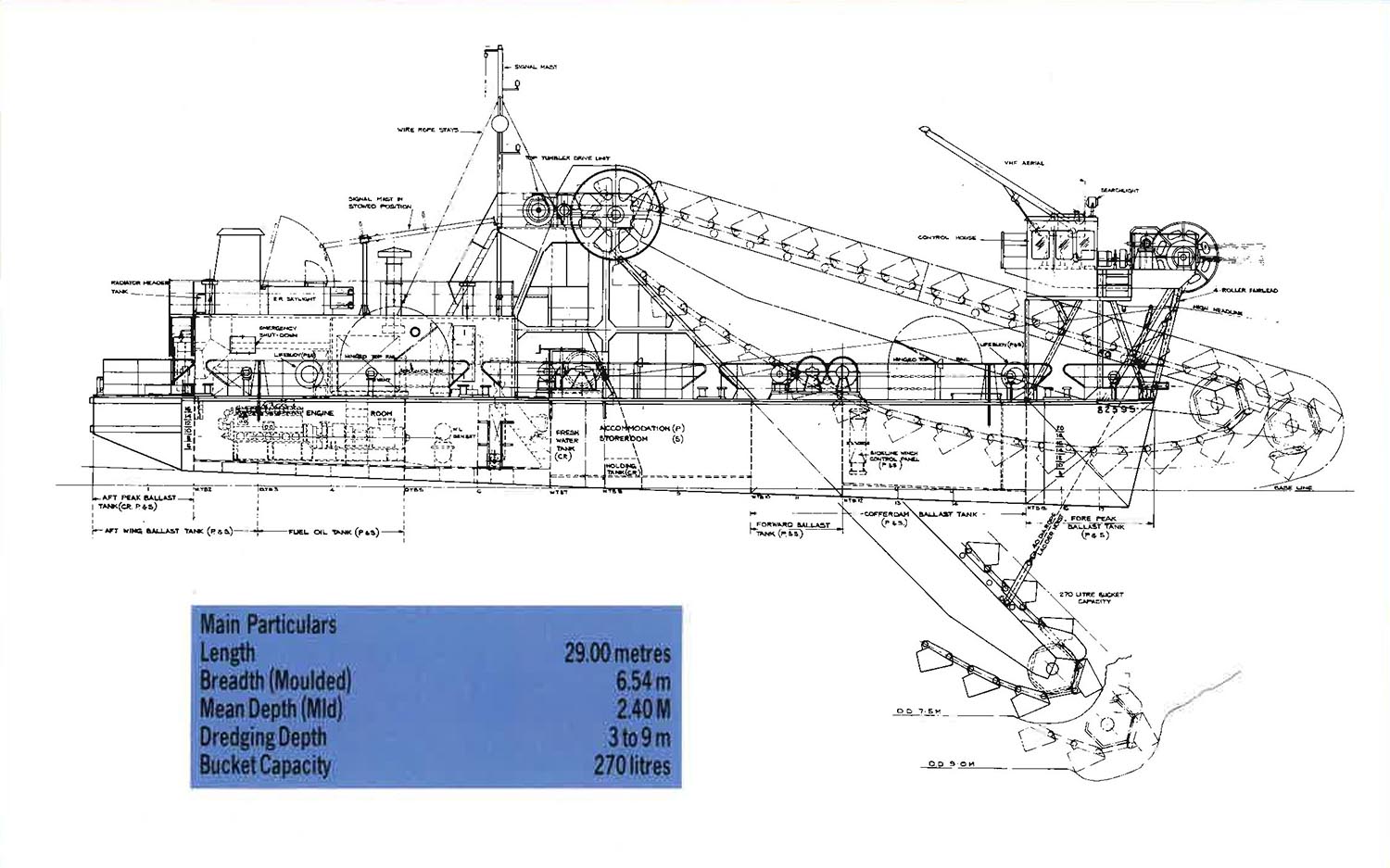

| Length | 29.00 m |

| Breadth (Moulded) | 6.54 m |

| Mean Depth (Mld) | 2.40 m |

| Dredging Depth | 3 to 9 m |

| Bucket Capacity | 270 litres |

N.P. Bucket Dredge

(Thomas Fletcher)

Designers: Seadrec Limited

Client

Location

One of a range of Seadrec Bucket Dredges this 250 M³/hour size was especially constructed to allow it to operate in very narrow waterways and canals, both its beam and air draught were designed to the minimum possible to allow it to pass beneath low bridges. It is nonetheless a heavy duty dredge which can easily handle 250 M³/hour of sand/silt, and when fitted with special rock picks can dredge dense solids, marl etc. at a reduced output. The dredge was built under special survey of Lloyds Register of Shipping to achieve the classification “Lloyds 100 A N Dredger – Protected Water Service”.

The hull is of all welded steel construction longitudinally framed. The forward end features cut aways to enable dredging close to dock walls etc. and the hull bottom has been designed to allow the dredge to sit on the river bottom at low tide. Other Seadrec versions are available.

Machinery

The machinery installation comprises a main diesel engine. Kelvin model “TA8” developing 255 B.H.P. at 1000 r.p.m. driving the Ward Leonard bucket drive generator, and the auxiliary alternator. Additionally a Lister type “HR4MA” air cooled marine diesel developing 43 B.H.P. at 1500 r.p.m. driving a 27 kW alternator is fitted to supply services when the dredge is not active. The auxiliary equipment includes general service, hull and fire pump, engine room bilge pump, fuel oil transfer pump, fresh water pump, oily water separator and air compressor.

Dredging Equipment

The bucket chain is driven by a 120 B.H.P. D.C. motor driving through a reduction gearbox and open gear transmission, the motor being supplied from a Ward Leonard Generator. The top tumbler is pentagonal in shape and runs in white metal pedestal bearings, the bottom being hexagonal in shape and running in phosphor booze bearings. The fabricated buckets are of 270 litre capacity with manganese steel brushes and pins with a weight of approx. 450 kg each, buckets having hard weld deposit on the bucket lips and may be fitted with ripping claws when dredging marl etc.

The ladder is manufactured in 3 sections thus providing a short or long ladder configuration allowing dredging up to a maximum depth of 9 m. The main ladder is fitted with 14 ladder rollers with additional 2 fitted on the extension ladder. These rollers are provided with an automatic motorised lubrication system which also feeds the top and bottom tumbler bearings.

Winches and Crane

The following winches are fitted to the dredge:

15 B.H.P. – Headline Winch

2 @ 10 B.H.P. – Sideline Winches

These winches supplied from Ward Leonard M.G. Set.

20 B.H.P. – Ladder Hoist Winch

Chute Hoist Winches

These winches supplied from A.C. circuit.

On top of the ladder gantry a simple robust manually luffing and slewing crane is fitted. Hoisting and lowering is achieved by means of an electric winch, crane lifting capacity 1000 kg, maximum outreach 4.2 m, minimum 1.5 m, length rope pull 15 m.

Control Cabin & Accommodation

The control cabin is of functional design with good all round visibility, and located on the forward shear legs. From this cabin all dredging operations are controlled such as:

Bucket chain drive

Ladder Hoist winch control

Headline & Sideline winch control

Chute winch control

The control cabin is connected to the engine room station and various points in the vessel by means of an intercom system. All controls are mounted in two control consoles which also house a bucket ladder dredging depth indicator and the deck lights, navigation lights and floodlights panel. The dredge is fitted with day accommodation for a crew of 4 men comprising a fully fitted messroom/galley and toilet compartment.