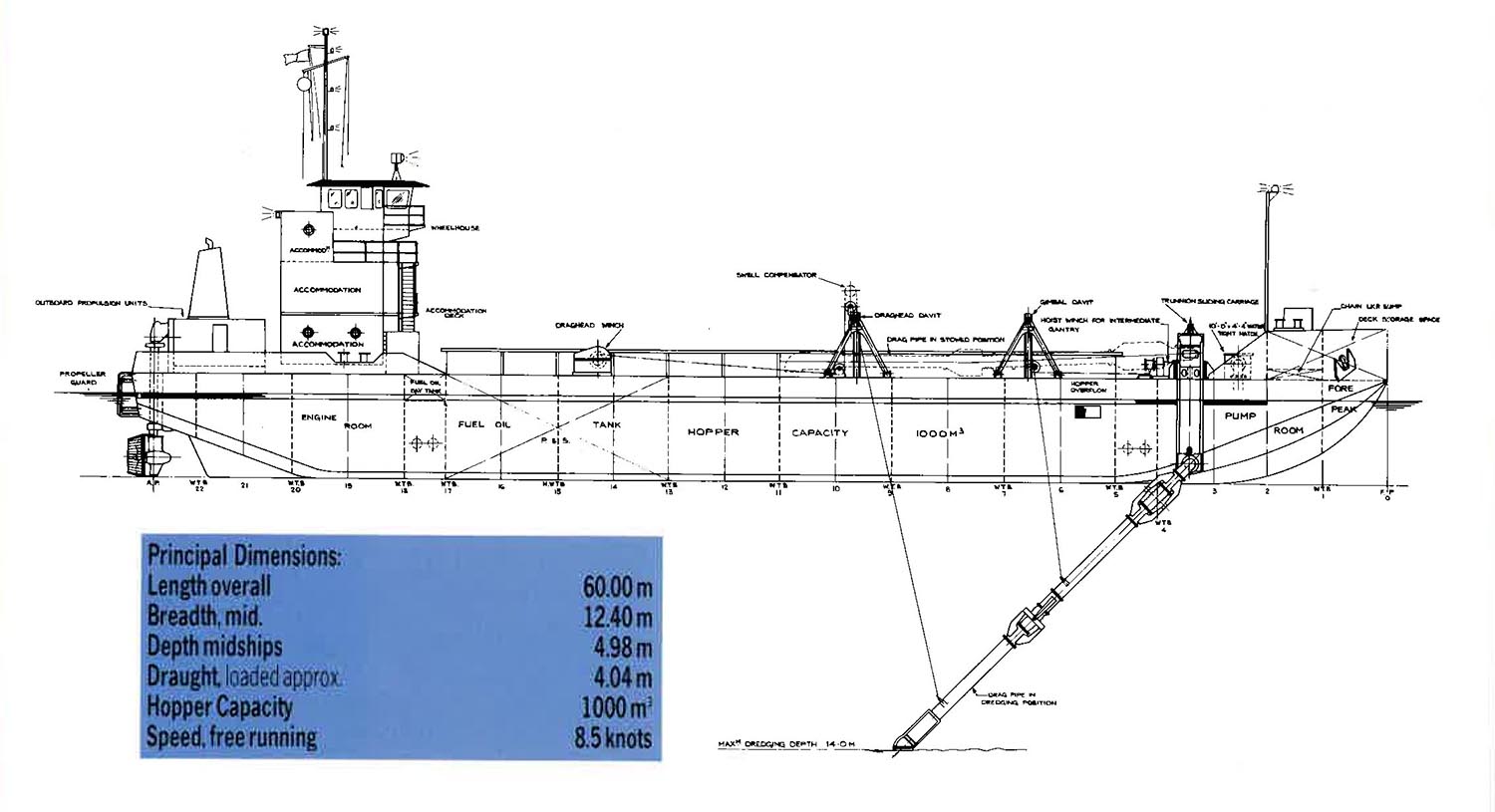

| Length Overall approx | 60.00 m |

| Breadth mid. | 12.40 m |

| Depth Midships | 4.98 m |

| Draught, loaded approx. | 4.04 m |

| Hopper Capacity | 1000 m³ |

| Speed, free running | 8.5 knots |

| Total Power | 2209 kW |

| Dredging Depth | 19.8 m |

| Suction Pipe Diameter | 0.56 m |

| Number of Dredging Pipes | 1 |

| No. of Engines | 2 |

| Engine Specs | Caterpillar - D398SCAC - 4Str - 12 cyl - 15.90 x 20.30 - rpm |

| IMO number | 7914248 |

| MMSI number | 366762660 |

| Callsign | WYR3417 |

| Vessel type | TSHD Split-hull |

| Owner | Cashman Equipment Corp. |

| Manager | JCI - Jay Cashman Inc. |

| Year Built | 1980 |

| Shipyard | Twin City Shipyard Inc. St. Paul - US |

| Yard number | 552 |

| Status | Active |

| Certification | U.S. Coast Guard Unlimited Oceans, ABS Class A-1 Dredging Services, ABS International Loadline, ABS Coastwise Loadline |

| Applications | Maintenance Dredging, Channel Excavation, Harbour Excavation |

1000M3 Splithull Hopper Dredge "Atchafalaya"

Designers: Seadrec Limited

Client

Operator: Gulf Coast Trailing Company, Louisiana, USA

Location

This 1000 M³ Split Hopper Dredge was constructed in accordance with the current rules of the American Bureau of Shipping for steel vessels under 61 metres (200 feet) in length and met requirements of the United States Coast Guard for vessels of this type achieving the Classification Maltese cross AI, Dredging Service, Unrestricted Ocean Service. The ‘Atchafalaya’ – was delivered in 1980to Contractors operating in the Gulf of Mexico and Eastern Seaboard of the United States of America.

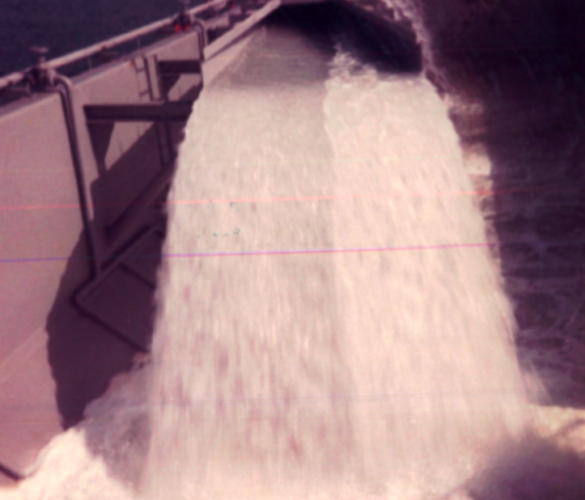

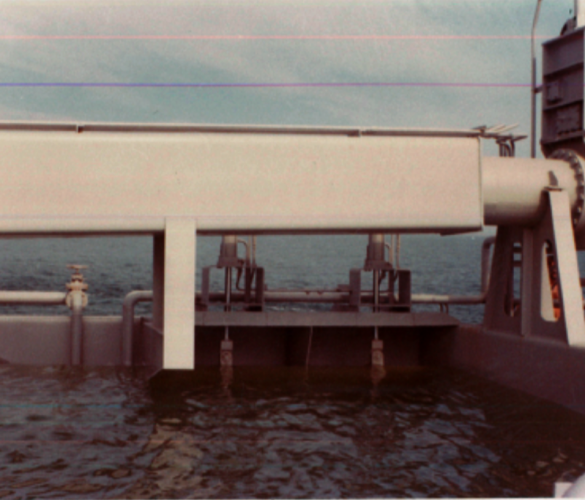

This is a simple Contractor’s Dredge designed for ease of operation and efficient results. The Dredging Installation is entirely Seadrec designed to achieve top quality balanced operation from Suction Head through Dredge Pump to Hopper Discharge. The hopper is designed to split longitudinally by means of hydraulic rams operated from the Control House, such that the entire hopper contents is required e.g. for land reclamation, the hopper may also be discharged by pumping out via a 500 mm bore pipeline up to 600 metres long.

Dredging Installation

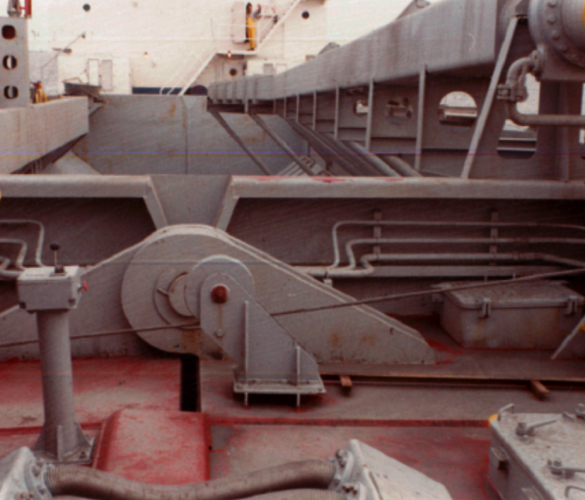

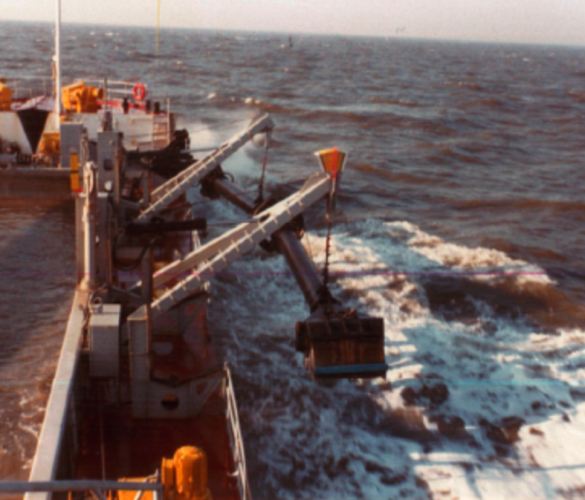

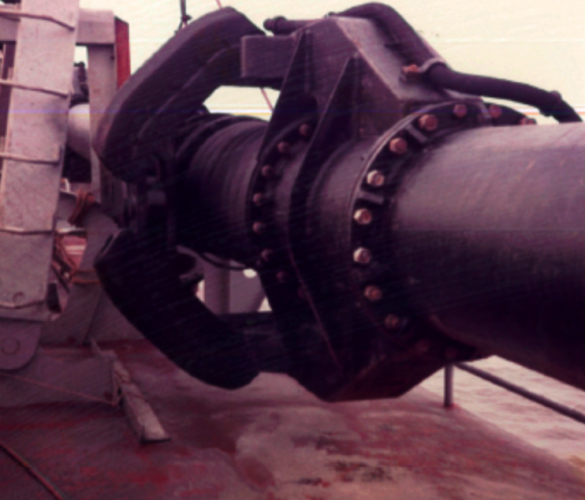

The dredge is fitted with a starboard-mounted articulated suction pipe of 550 mm bore designed for a normal dredging depth of 45 ft with a maximum dredging depth of 65 ft by use of an extension spool.

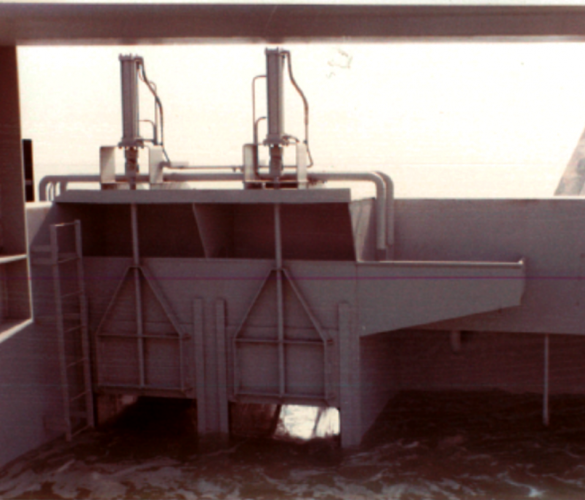

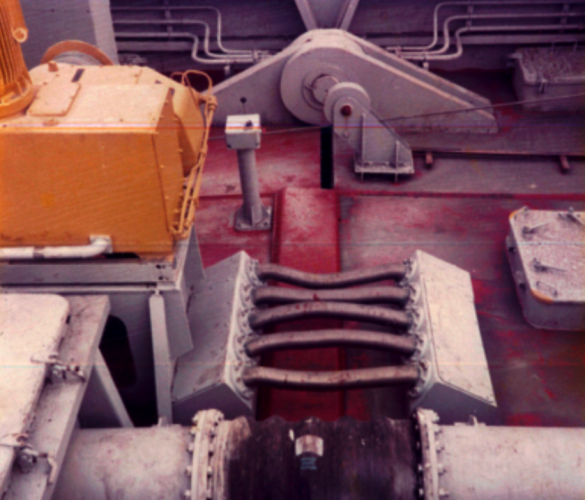

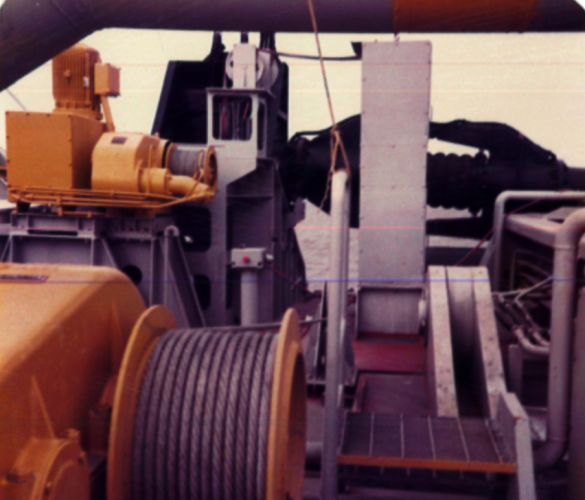

- Dredge pump of centrifugal single inlet type with 4 bladed overhung impeller. The pump is driven by an electric motor of 500 kW, through a belt and pulley drive.

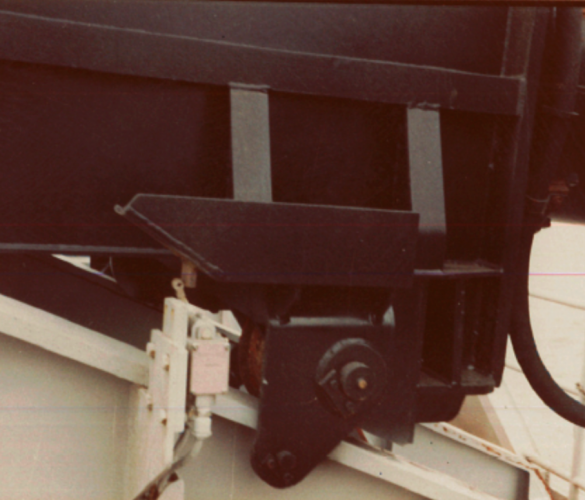

- Thee suction pipe gantries – one suction head, one intermediate, and one trunnion gantry – each actuated by means of locally sited electric/hydraulic winches operated from the Control House.

Automatic Light Mixture Overboard Installation

Should the density of solids passing through the dredge pump be below a specified level, the mixture will automatically be returned to the sea, and only discharged to the hopper when a satisfactory density level is reached.

Velocity, Density and Protection Metres

By means of these instruments, the operator can closely control his dredging performance – and records may be kept of actual performance achieved.

Draft and Load Indicator

Suction Pipe Position Indicator

Situated at the operator position this indicator mimics the actual position of the suction pipe and head, and greatly aids efficient dredging operations.

Suction Mouthpiece Compensating Gear

This automatically adjusts should the dredge be operating in swell conditions and compensates for vertical movements up to 1.50 metres.

Propulsion

By means of two deck-mounted rudder propeller units, each unit being powered by diesel engine developing 720 hp at 1800 rev/min to give the ‘Atchafalaya’ a loaded speed of 8.5 knots.

Navigational Equipment

– Radar unit with maximum range of 16 miles

– Standard Navigational Equipment fitted.

Accommodation

Accommodation is comprehensive with ample air-conditioning/heating in all cabins. Accommodation arranged for a crew compliment of 14 as follows:

2 – Single-berth cabins

4 – Double-berth cabins

1 – Four-berth cabins

1 – Galley/Messroom – fully fitted

1 – Hospital

Toilets and Shower Room.