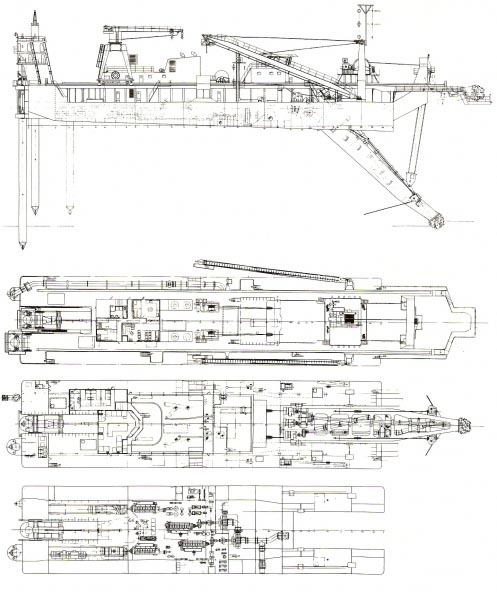

Seacut 12500 N.P. Cutter Suction Dredge

Designers: Seadrec Limited

Client

Location

The Seacut 12,500 is the largest and most powerful Cutter Suction Dredge ever to be built in the U.K.

Intended for operation in tropical and sub-tropical conditions with attendant high ambients in temperature and humidity, the machinery spaces, control areas and accommodation are generously rated in the air conditioning and ventilation.

The Dredge meets Classification requirements of the highest class of Lloyds to achieve the notification 100 Al Dredge ‘Extended Protected Waters Service’.

Features

Reflecting the highest State of the Art of Large Cutter Suction Dredges, the Seacut 12,500 incorporates the following features:

- Fixed Manoeuvring Spud

- Travelling Dredging Spud

- Maintenance Crane Covers entire length of vessel

- Hinged Cutter Maintenance Platform

- Anchor Booms

- Air-conditioned Engine Room Monitoring Station

- Central Control Station with all round vision

- Rated for continuous operation

- High degree of automation/output control

- Interchangeability of operating plant

The Seacut 12,500 has separate spaces for generator Room, Engine Room and Pump Room. Two identical Mirrlees Blackstone MB 275 Diesel engines each delivering 2775b.h.p. at 900 r.p.m. drive, respectively, the generators (two cutter generations, main and standby alternators, and underwater pump generator) whilst a further two MB 275 engines drive the twin inboard dredge pumps. A further underwater dredge pump is situated on the Suction Frame.

Interchangeability/byepassing of the dredge pumps is a particular feature.

The Suction Frame is of massive construction designed specifically to ensure maximum bearing on the sea bed of the 2000 b.h.p. Cutter. This is driven by two electric motors driving through a reduction gearbox and shaft drive. The Cutter is capable of cutting a wide range of coral and rock with the entire drive capable of absorbing transient torque reversals up to four times full load torque.

The entire frame with drive and underwater pump weighs in excess of 475 tonnes with the cutter gearbox itself weighing 54 tonnes. Diameter of cutter shaft is 500 mm.

Seacut 12,500 can discharge to pipelines up to 6,000 metres in length and can produce outputs in medium sand of up to 3500 m per hour. A comprehensive system of production control is incorporated.

Raising and lowering of the fixed and traveling spuds is performed hydraulically, as is the movement of the spud carriage carrying the dredging spud. Winches for operation of suction frame hoist , sidelines wires, and anchor booms, are electrically powered.

Accommodation is comprehensive and entirely air-conditioned, with newsroom, captains, cabin, office, toilets, fully fitted galley and store rooms, and sleeping accommodation for 15 persons.

The dredge is fitted with an electrically operated travelling crane, capable of travelling the full length of the dredge and handling all components for normal maintenance purposes.

Seadrec provided the complete design of the dredger as well as incorporating Seadrec dredging equipment.Vessel built at Appledore Shipbuilders, UK and then transported by heavy lift ship to Cuba.