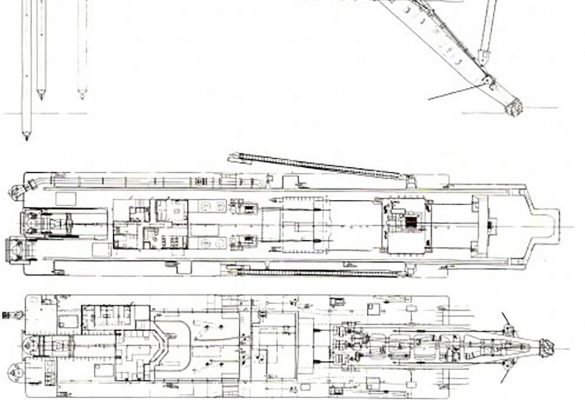

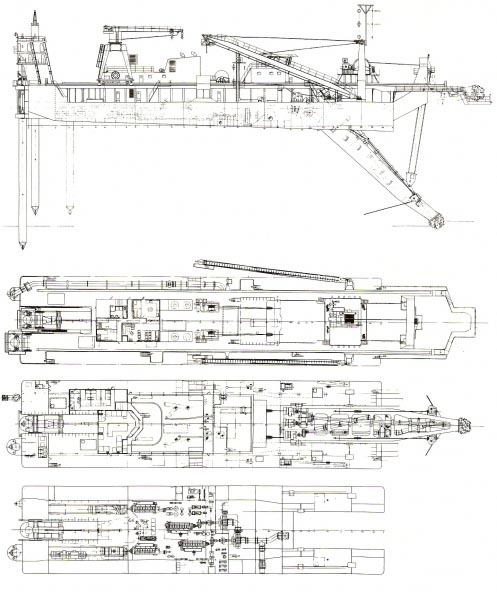

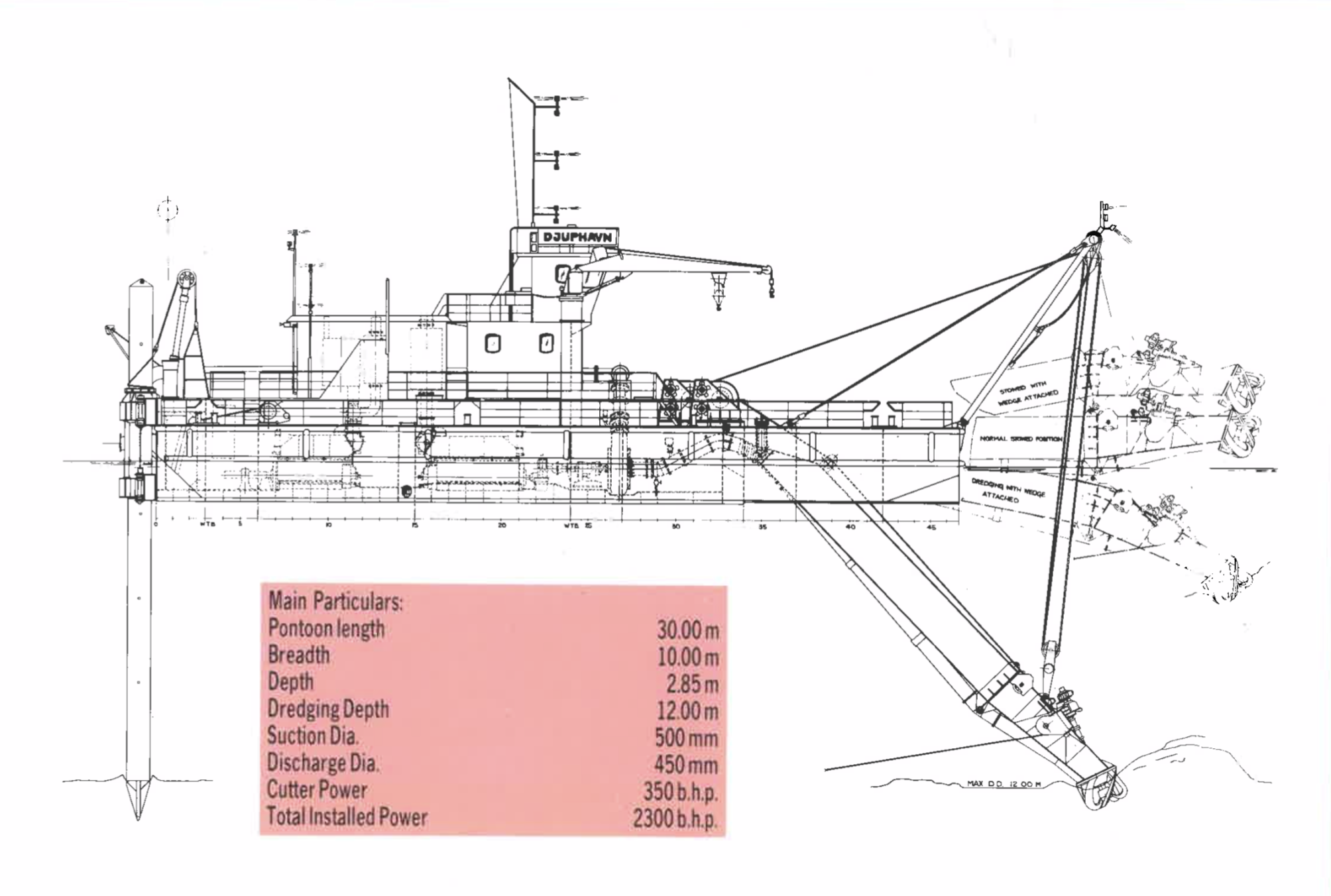

Seacut 2300 Cutter Suction Dredge

Designers: Seadrec Limited

Client

Location

Constructed for the Norwegian Coastal Directorate this Seacut 2300 Cutter Suction Dredge is specially designed to be suitable for the very cold and arduous climate conditions which exist in the Norwegian northern coastline. The “Djuphavn” will be used for the maintenance of ports and fishing harbours from the far north to the very south of Norway and has been designed for towage in coastal waterways under all customary precautions.

It discharges to pipeline lengths of up to 1500 metres.

This modern Cutter Dredge is built to comply with the requirements of the Norske Veritas 1AI R 45 Dredger and the Norwegian Maritime Directorate rules for ‘Liten Kystfart’.

Technical Features

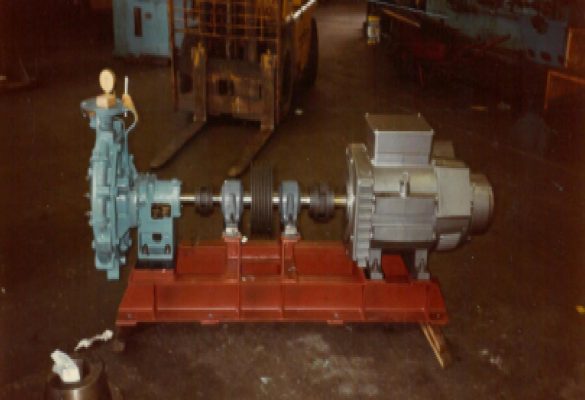

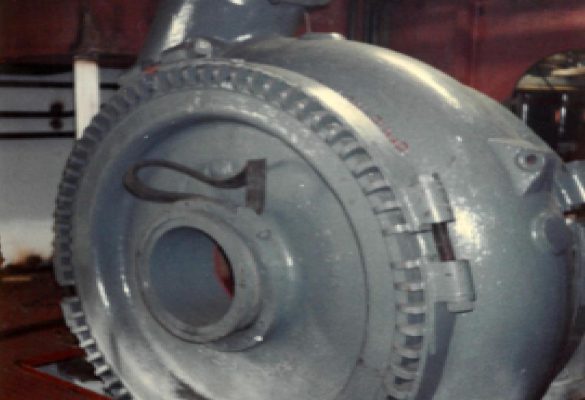

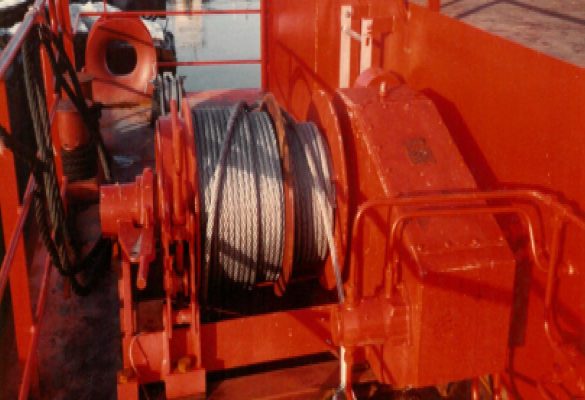

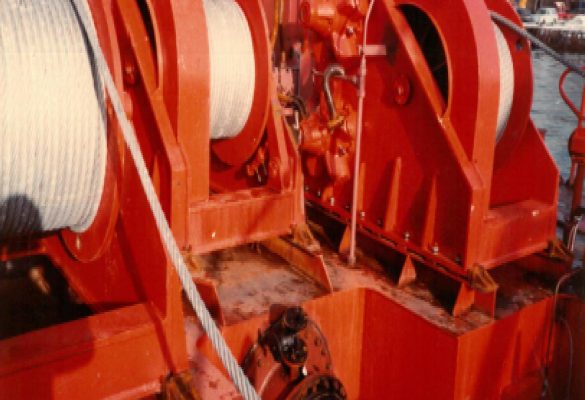

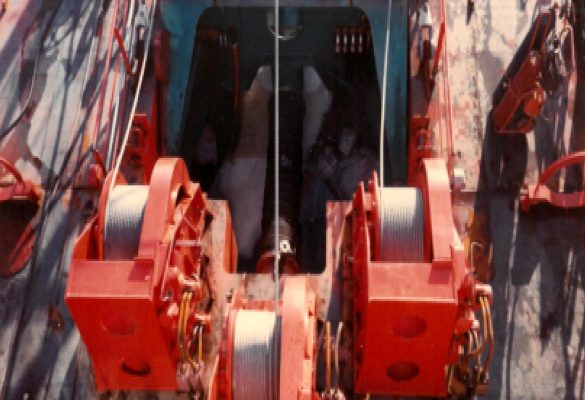

This Cutter Dredge employs all the desirable features of hydraulically powered dredges of this type –simplicity and ease of operation and maintenance – combined with the custom design of the robust monohull and dredging equipment for the Norwegian operating conditions. The very robust monohull is of al welded steel construction, with extra reinforcement incorporated in way of all areas of stress and heavy wear. The control house and accommodation module are flexibly mounted on the main decking fully insulated to reduce noise levels to a minimum and maximise operator comfort and efficiency.

This is the second specialised dredge contract which Seadrec has won from Norway in recent years, the former being an 80 ton bale pull Dipper Dredge, which very comfortably exceeded all specification requirements during trials and subsequent operational period.

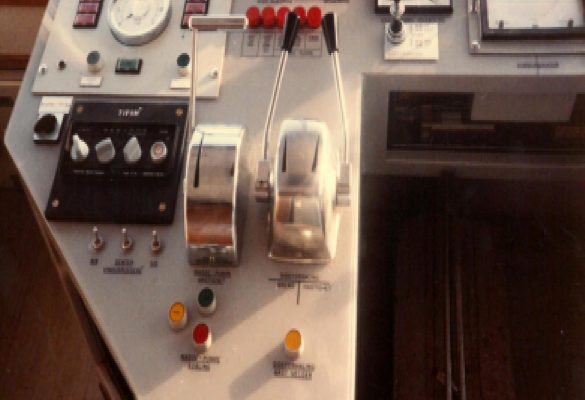

Air-conditioned daytime accommodation comprising Messroom/Dayroom and toilet facilities are provided for a crew of 3. The dredge operator’s cab is located above the accommodation deck and fitted-out with all controls for one-man operation. Crew quarters and engine room are specially insulated and heated to enable continuous working under the extreme climatic conditions prevailing in the north of Norway.

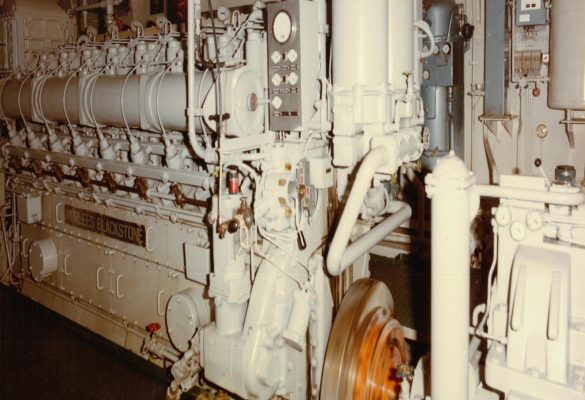

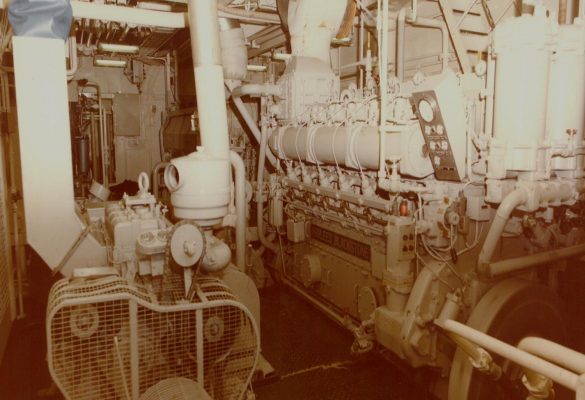

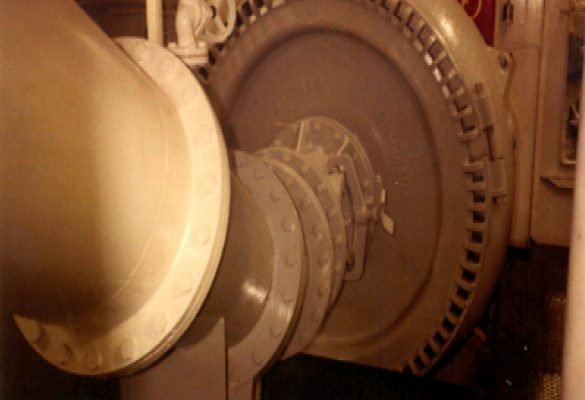

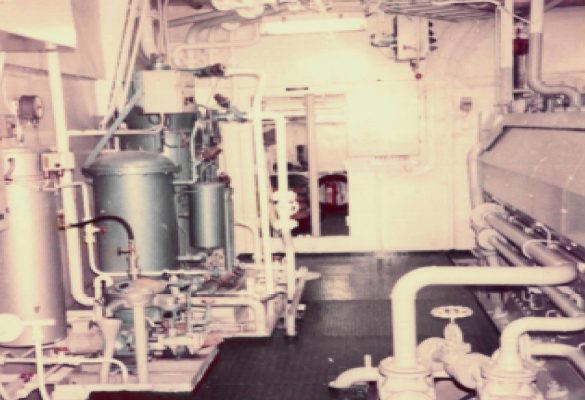

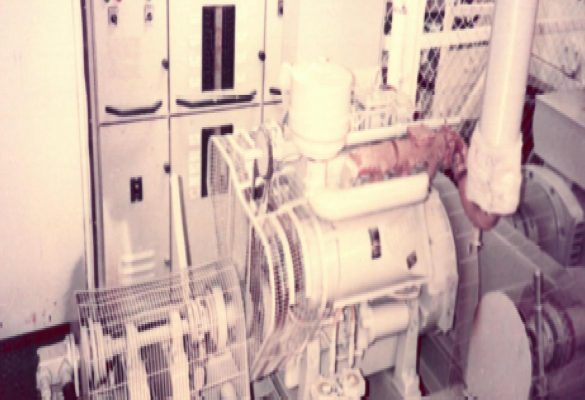

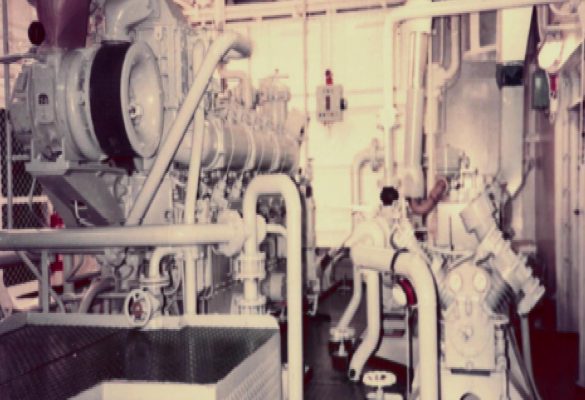

Power for the dredge pump is supplied by a Mirrlees Blackstone ESL8MA Mark 2 marine diesel engine developing 1430 b.h.p. at 1000 r.p.m. Auxiliary power for all systems is supplied by a Mirrlees Blackstone ESL6MA Mark 2 marine auxiliary diesel engine developing 800 b.h.p. at 750 r.p.m. A small stand-by diesel generator is fitted to supply power for harbour duty and necessary services when the dredge is shut down.

The engine room is provided with an engineer’s workshop and store facilitate on board maintenance and repairs. Additionally a hydraulic jib crane is situated on the main deck for handling spares and stores.

The Vessel complies with, and was built under the supervision of Set Norske Veritas Classification Society for the Notation: “+A1 R45 Dredger”.

The year of construction was in 1982 at Ankerløkken Glommen Verft, Frederikstad then rebuilt and modified by Vegsund Slip, Ålesund in 1995.