[rank_math_breadcrumb]

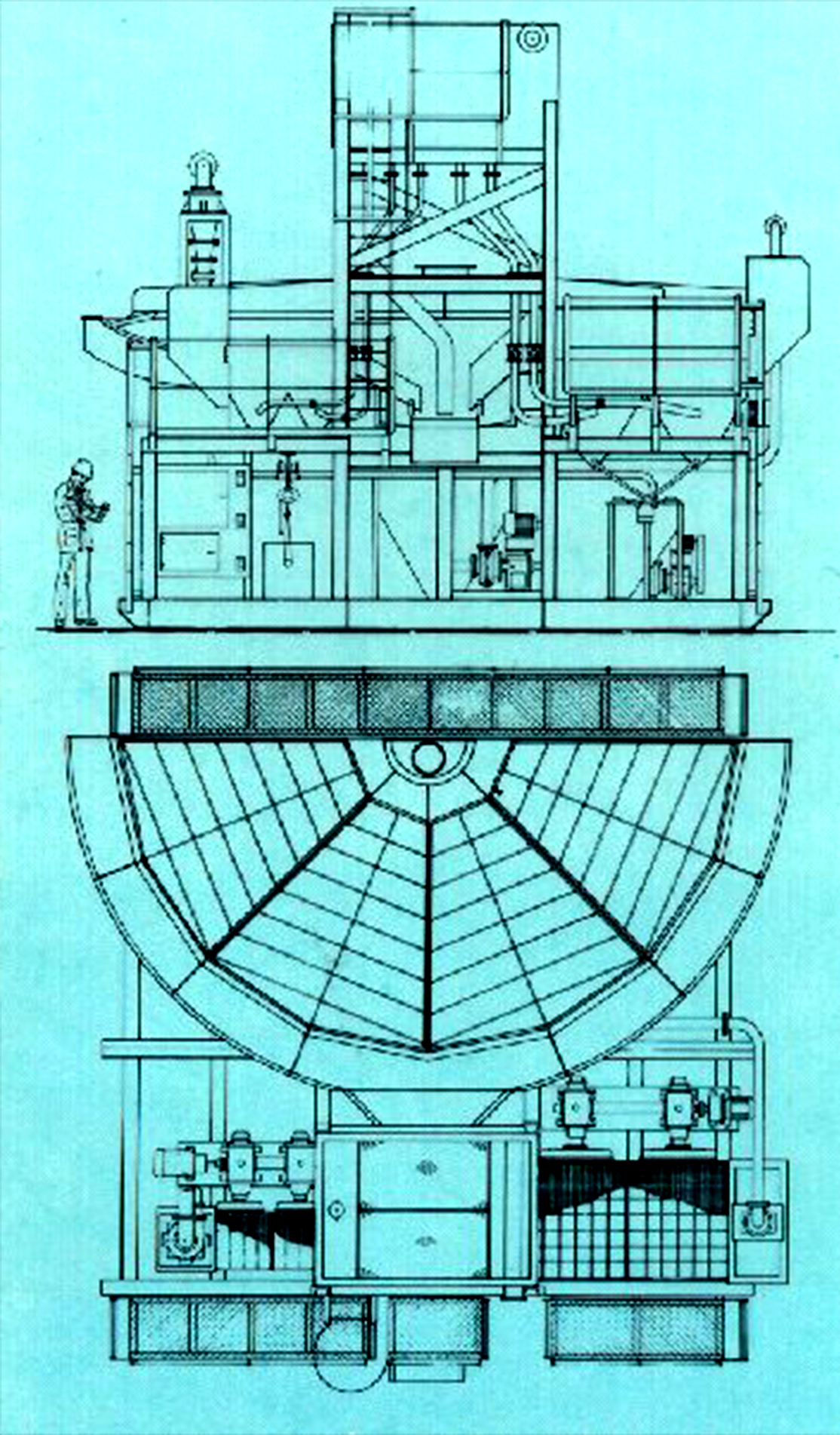

| Primary Jig | 4 Segments of a 6.4 m dia A.D.L. radial jig |

| Secondary Jig | 2 cell 1.2 m x 1.1 m A.D.L. rectangular jig |

| Tertiary Jig | 2 cell 0.6 m x 0.6 m A.D.L. rectangular jig |

| Primary Concentrate Pump | 80 mm bore delivery 30 cu.m/hr @ 8 m head |

| Secondary Concentrate Pump | 50 mm bore delivery 20 cu.m/hr @ 8 m head |

| Installed Power | 20 kW |

| Weight Empty | 23 t |

| Plant supplied in modular form to comply with the clients requirements |

Mobile Gold & Diamond Recovery Jig Plants

Designers: Alluvial Dredges

Client

Harrison Western

Location

Construction: Ayrshire, Scotland Operation: Alaska

A.D.L. have developed a range of Mobile Gold and Diamond Recovery Jig Plants. Every self contained plant is designed to comply with the requirement of the client’s project and incorporates the very latest mineral separation technology thus ensuring maximum recovery efficiency for minimum investment.

The complete plant is either mounted on skids or a floating pontoon system and can be designed to treat a feed of between 15 and 150 cubic metres per hour of minus 10 mm prescreened undersize material.

This A.D.L. mobile gold recovery plant was designed to receive a feed of 75 cu.m/hr. of prescreened minus 10 mm material from the client’s existing plant.