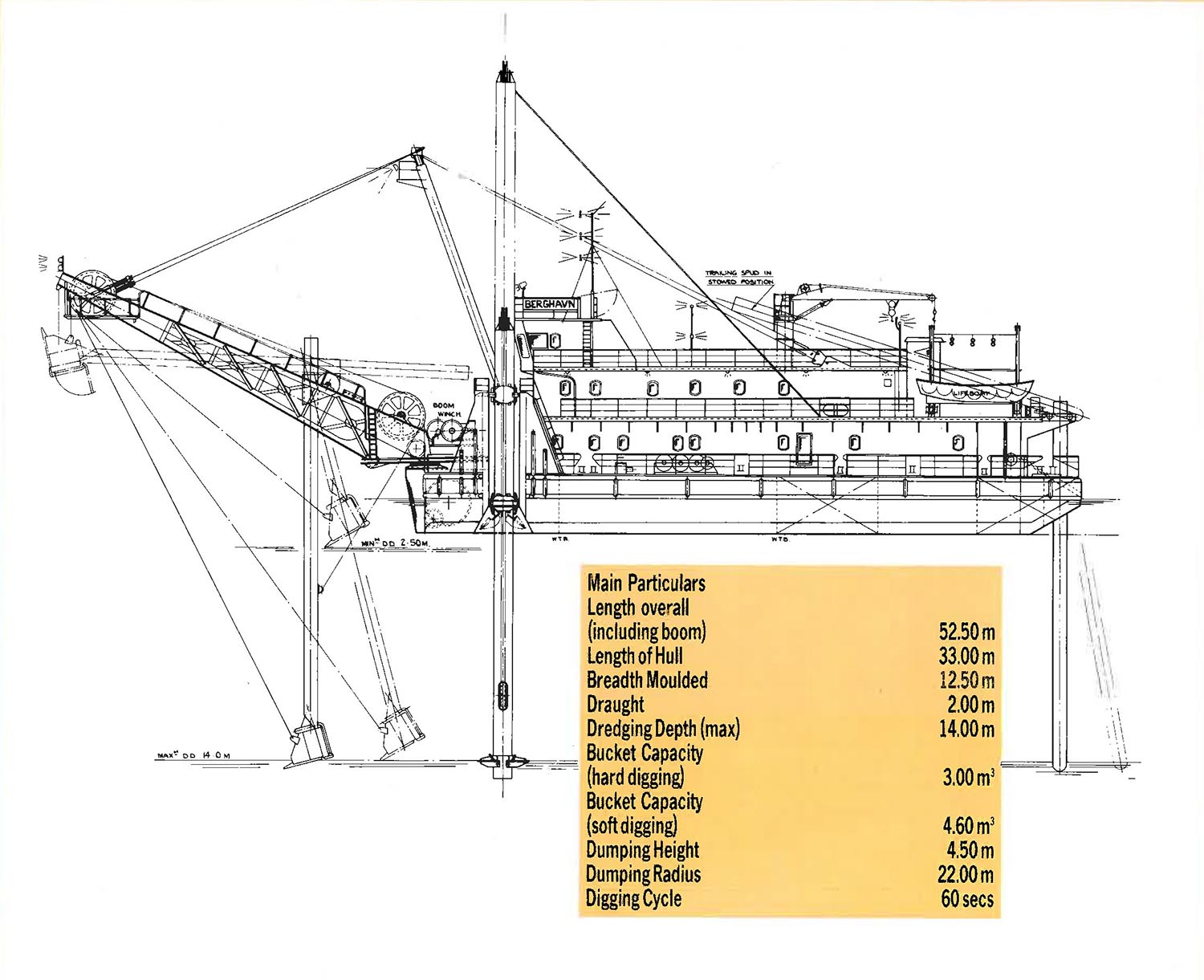

N.P. Dipper Dredge

Designers: Seadrec Limited

Client

Location

The robust mono-hull is of all welded steel construction specially reinforced in high stress areas where the heavy dredging loads are transferred via the digging machinery to the hull structure.

The entire operation of “Berghaven” is controlled by one man from the well laid-out control house located above the accommodation deck. Air-conditioned accommodation is provided for a crew of eleven crewmen in single-berth cabins and incorporates separate TV room, messroom, galley and freezer storage for extended working provisions. All accommodation and machinery spaces are specially insulated and heated to extremely high standard to allow continuous working under the extreme climatic and dredging conditions prevailing in the Norwegian north. The “Berghaven” can truly work in conditions which no other dredge type can tackle.

All machinery is of well-tried and proven SEADREC design and constructed to readily withstand the heavy fluctuating stresses imposed by its rugged environment. The bucket has a capacity of 4.60 cubic metres for normal digging whilst a smaller capacity 3.0 cubic metre bucket is fitted for the heavy digging of rocks and obstructions.

The dredge is fitted with two dipper arms, a long arm for 6.5 – 14 metres depths. Two aft breast spuds and one centre line “trailing” spud forward are fitted, designed to operate to depths down to 14 metres with an allowance of 2 metres for bottom penetration.

Power for the dredge is provided by a Mirrlees Blackstone ESL6MA marine Diesel engine developing 700 BHP @ 750 rev./min; this engine drives the Ward Leonard generator for the main hoist winch together with, in tandem, the AC main alternator. An R.A. Lister JWS 6MA Diesel engine developing 140 BHP @ 1,500 re./min drives a 50 KW auxiliary alternator and is clutch coupled to an emergency 33 KW DC generator for the spud hoist winch. The dredging winches are supplied and controlled by a sophisticated yet minimum maintenance electrical installation with current provided by Ward Leonard generators.

During trials “Berghavn” produced a digging “bail” pull in excess of 80 tonnes and comfortably exceeded all specification requirements. It is the most powerful dredge of its type built for the Owners.